Home > Products > Steel Billet Induction Heater > Billet Induction Heat Treatment System

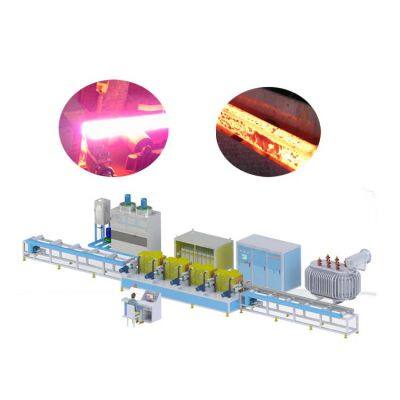

Billet Induction Heat Treatment System

- tian jin

- T/T L/C

- 40 days

You May Like

Product Description

Equipment power

1000KW-12000KW

[Equipment frequency] 500HZ-1200HZ

Production capacity: 40-300t/h

[Workpiece size] 120mm-160mm square billet, length 3000mm-12000mm

【 Applicable workpieces 】 Steel billets, square pieces, square steel, etc

Energy Conversion: Depending on the temperature of the damaged surface of the steel, it consumes tens to tens of degrees of electricity per ton

Process characteristics of continuous casting billet heating production line:

The integrated design of the feeding and discharging mechanism, coil, and power supply requires less infrastructure, factory space, and installation time. The series intermediate frequency power supply design converts AC voltage into DC voltage through diodes, with an energy conversion efficiency of 94%. The output power of the continuous casting billet heating production line can be adjusted between 10% and 100%, and all power ranges can maintain a power factor of 0.94 with minimal harmonic distortion pollution. Dynamically monitor the load current changes of the series resonant coil, timely closed-loop control the power output power, ensure stable heating temperature, and select different heating frequencies according to the size of the billet to save power consumption; The coil adapts to a diameter range of 1 times wider than the billet. The embedded control panel displays the machine's operating status and is used for fault diagnosis; You can choose between manual or human-machine interface operation mode. Power supply system: Dual rectifier 12 pulse or 24 pulse KGPS1000-1000KW, single medium frequency power supply can be used independently or multiple power supplies can be used in parallel. Install dedicated transformers on the continuous casting billet heating production line to reduce the impact of harmonics on the power grid. Users can use it with confidence, safe and reliable. Control system: The entire heating process is automatically controlled by PLC, and production records such as heating quantity are displayed in a timely manner. This console is designed for standalone use, with a specially customized human-machine interface, highly user-friendly operation instructions, fully digital and deep adjustable parameters, and a one click restore function. It is easy to operate. Feeding and guiding system: Each axis is driven by an independent motor reducer, with multiple axis drives and a single frequency converter control to synchronize the operation of multiple axes. The components are selected from well-known brands, with reliable quality and stable operation. Using 304 non-magnetic stainless steel guide wheels, the axial elasticity of the guide wheels is maintained to adapt to the allowable bending range of the steel. All cabinets are sandblasted, sprayed with plastic, and baked with paint, and all waterways are made of thick walled stainless steel. The equipment is corrosion-resistant and has a long service life. The equipment is equipped with a large LCD temperature display screen (convenient for on-site personnel to observe and display data).

Overseas manager: Tom Wang

Email:tom@foreverfurnace.com

Phone: 0086-13303078975(whatsapp, wechat,line)

Specialist of induction heat treatment furnace in China; Glad to be your business partner in induction heating field.

Contact Us

- Hebei YuanTuo Electromechanical Equipment Mnufacturing Co.Ltd.

- Contact nameTom Chat Now

Product Categories

New Products

-

Steel ball heating furnace for heat treatment

-

2500KW steel billet induction heating equipment

-

Induction heating equipment for hot rolling of steel billets

-

billet induction reheating furnace

-

Steel billet continuous casting and rolling heating furnace

-

Steel sheet Induction Hardening Heat Treatment Machine

-

Induction Steel Plate Hardening Heat Treatment equipment

-

Steel Plate induction heating system

-

Plate induction heating hardening production line

-

Drill Pipeline Induction Hardening And Tempering Machine

-

Steel pipe heat treatment equipment furnace

-

seamless pipe induction heat treatment furnace

Popular Searches

- induction heating equipment

- induction heater

- induction furnace

- induction melting furnace

- heat treatment

- induction heating machine

- induction machine

- induction heating power supply

- induction heating generator

- induction heat treatment equipment

- medium frequency induction heating

- induction heat treatment machine

- induction billet heater

- induction power supply

Recommended Products

- 3000W CW Handheld Laser Cleaning Rust Removal Head Laser Paint Removal Cleaner for Metal Laser Cleaning Machine

- Best-Selling 1000W Precision Parts Pulse Laser Cleaning Machine Rust Removal Mold Cleaner for Metal Wood Stone Aluminum

- 1500W Handheld Fiber Laser Cleaner for Metal Stainless Steel Copper Rust Paint Removal on Wood Stone Aluminum

- The surface of the impeller is strengthened by spraying

- Mopa Laser Cleaner 500W 1000W Pulse Laser Cleaning Remove Rust with Laser Machine

- 100W Handheld Pulse Laser Cleaning Machine Portable Rust Paint Removal with Air Cooling System

- Hot Sale 1500W-3000W Fiber Laser Cleaning Machine for Auto-parts Stone Metal

- Portable 50W 100W Backpack Mini Laser Cleaning Machine Fiber Laser Rust Remover for Wood Stone Stainless Steel Industrial Use

- 1500w Air Cooled Laser Cleaning Machine Rust Removal Handheld Fiber Cleaning Machine for Rust Paint Removal

- 1500w Air Cooled Laser Cleaning Machine Rust Removal Handheld Fiber Cleaning Machine for Rust Paint Removal

- 1500W Continuous Laser Cleaning Machine Handheld Laser Rust Removal Machine

- Portable Pulse Laser Cleaning Machine 50w100w Stone Graffiti Old Paint Laser Rust Removal Machine Price

Find Similar Products By Category

- Manufacturing & Processing Machinery > Metallic Processing Machinery > Metal Processing Machinery Parts

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

Tom

Hi there! Welcome to my shop. Let me know if you have any questions.

Tom

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile